R&D and Product Innovation: Our Research and Development team is continually exploring new materials, technologies, and processes to push the boundaries of what is possible in medical device manufacturing. We leverage cutting-edge tools and technologies to create products that are at the forefront of the industry.

Expert Technicians: Our team of highly skilled technicians brings years of experience to the table. Trained in the latest manufacturing techniques and industry best practices, they ensure that each instrument meets the exacting standards of the medical field.

ERP Software for Production Management: We leverage State of the art ERP software to optimize our production management. This advanced software enhances our manufacturing processes by enabling real-time monitoring, precise scheduling, and efficient resource allocation. By integrating ERP Software, we ensure that every stage of production meets our high standards of quality and efficiency.

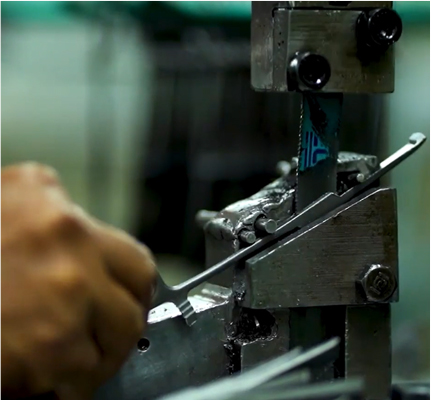

UDI Marking for Traceability: We implement Unique Device Identification (UDI) marking on all our products to ensure full traceability. This critical process enhances patient safety by allowing the tracking and identification of devices throughout their lifecycle.

Quality Control: Quality is ingrained in every step of our manufacturing process. We employ rigorous quality control measures, including inspection under magnifying glasses & microscopes, to detect and correct any imperfections. This meticulous attention to detail ensures that our products are flawless and meet stringent international standards.

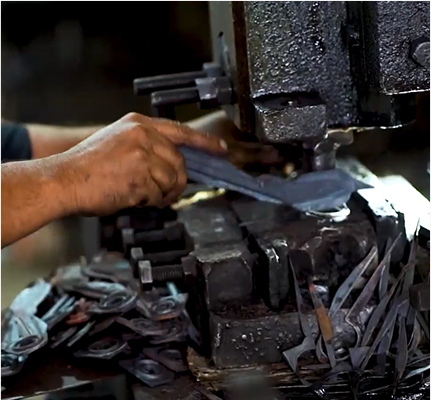

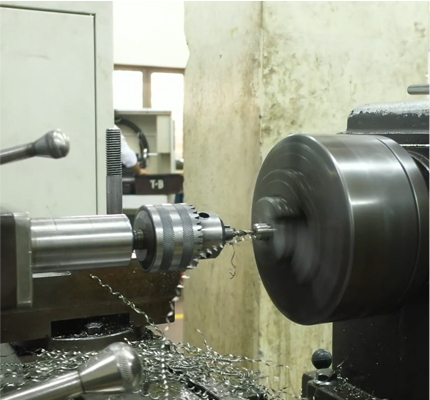

CNC Machining: Our state-of-the-art CNC machining processes guarantee precision and consistency in the production of our instruments. By employing advanced CNC technology, i.e. CNC wire cutting, CNC Lathe, Shapper Machine, Shot Blast etc. we achieve high accuracy, intricate designs, and superior product quality.

Heat Treatment & Surface Finishing: We employ specialized heat treatment processes to enhance the mechanical properties of our instruments, such as hardness and durability. Our surface finishing techniques, including passivation and electro-polishing, ensure corrosion resistance and a sterile surface.